Roar Solutions - An Overview

Roar Solutions - An Overview

Blog Article

Indicators on Roar Solutions You Need To Know

Table of ContentsThe Buzz on Roar SolutionsRoar Solutions for BeginnersRoar Solutions Fundamentals ExplainedSome Ideas on Roar Solutions You Should Know

The tools register is a detailed database of devices documents that includes a minimum set of fields to determine each thing's area, technical criteria, Ex-spouse category, age, and ecological information. This details is vital for monitoring and managing the tools successfully within unsafe areas. In contrast, for routine or RBI sampling assessments, the grade will certainly be a mix of In-depth and Close inspections. The proportion of In-depth to Close assessments will be identified by the Equipment Danger, which is assessed based upon ignition risk (the possibility of a source of ignition versus the probability of a flammable environment )and the hazardous location category( Area 0, 1, or 2). This variation will likewise influence the resourcing requirements for job prep work. As soon as Whole lots are defined, you can develop sampling plans based on the example size of each Great deal, which describes the number of random tools things to be inspected. To figure out the needed sample dimension, 2 aspects need to be reviewed: the size of the Lot and the classification of evaluation, which suggests the level of effort that ought to be used( minimized, typical, or increased )to the examination of the Lot. By incorporating the classification of evaluation with the Lot size, you can then develop the appropriate rejection requirements for a sample, implying the allowable variety of faulty things found within that sample. For even more details on this procedure, please refer to the Energy Institute Standards. The IEC 60079 typical advises that the optimum period in between inspections ought to not surpass three years. EEHA assessments will certainly also be carried out outside of RBI projects as part of arranged maintenance and tools overhauls or repair services. These examinations can be attributed towards the RBI example sizes within the impacted Whole lots. EEHA assessments are carried out to recognize mistakes in electrical tools. A weighted racking up system is necessary, as a solitary tool may have numerous faults, each with differing degrees of ignition risk. If the consolidated rating of both assessments is less than two times the fault rating, the Whole lot is considered acceptable. If the Great deal is still thought about unacceptable, it should go through a complete examination or validation, which might cause more stringent inspection protocols. Accepted Great deal: The sources of any kind of mistakes are identified. If an usual failing mode is located, added tools may need inspection and repair work. Mistakes are identified by extent( Safety and security, Stability, Housekeeping ), ensuring that immediate concerns are assessed and addressed without delay to mitigate any kind of influence on security or operations. The EEHA data source need to track and tape-record the lifecycle of mistakes together with the corrective actions taken. Applying a robust Risk-Based Examination( RBI )strategy is essential for guaranteeing conformity and safety in taking care of Electric Tools in Hazardous Areas( EEHA). Automated Mistake Rating and Lifecycle Administration: Easily handle faults and track their lifecycle click this link to boost inspection precision. The introduction of this assistance for risk-based assessment even more enhances Inspectivity's placement as a best-in-class service for regulatory compliance, as well as for any asset-centric assessment usage case. If you are interested in finding out more, we welcome you to request a demonstration and uncover how our solution can change your EEHA monitoring procedures.

With over ten years of consolidated Ex experience (IECEx/ATEX, EEHA), Saipex began to promote the importance of capability of all workers involved in the Hazardous Location field in 2019. In 2021, our collaboration with IndEx and Technology Skill International (TSI) noted a landmark in the Saipex road to proceed Ex-spouse improvement.

More About Roar Solutions

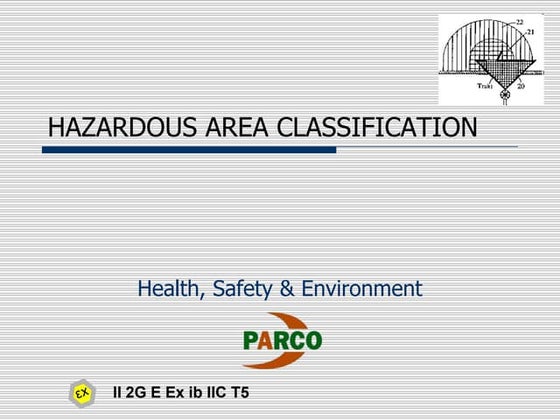

In terms of eruptive risk, an unsafe area is an environment in which an explosive environment is existing (or might be expected to be existing) in amounts that require special precautions for the building, setup and usage of devices. In this article we explore the challenges faced in the work environment, the risk control steps, and the called for competencies to function safely.

(https://www.dreamstime.com/thomascarrillo4740_info)

These compounds can, in specific problems, develop eruptive ambiences and these can have significant and terrible effects. Many of us are familiar with the fire triangular remove any kind of one of the three components and the fire can not occur, but what does this mean in the context of dangerous locations?

This is after that confirmed via assessment and testing and is preserved throughout the life of the setup by using the appropriate maintenance strategies, supplemented by regular examination. When all these actions are taken, they must additionally be recorded. The verification dossier includes information such as the harmful area category drawing, makers' documentation, devices accreditation, layout illustrations and calculations, inspection documents, and documents of an individual's proficiency and proceeding professional development (CPD), such as by means of ECA's eCOMS software program.

The Best Guide To Roar Solutions

It is vital that trainees recognize and have a comprehensive understanding as to just what comprises an unsafe location. The student ought to likewise recognize why training is essential before attempting to handle job or specifying equipment into a dangerous location. These locations are additionally called classified places and are defined as areas which have a high likelihood of a surge since of the feasible presence of combustible gases, vapors, cleans and so on.

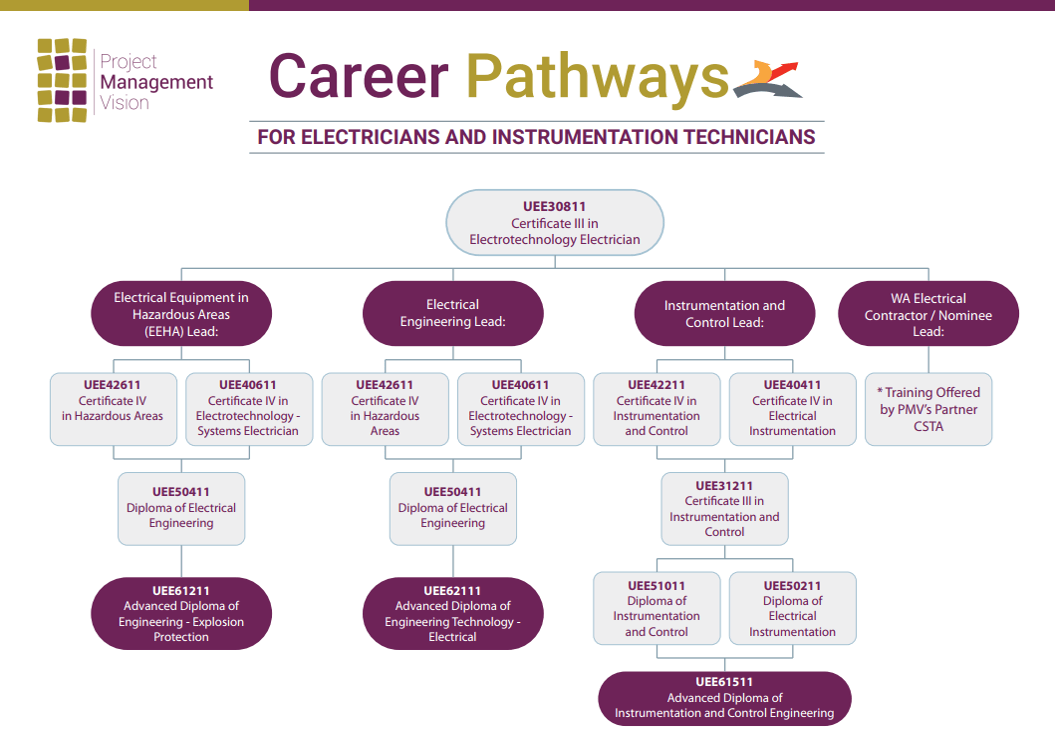

Industries which contain harmful areas are now requiring that electric workers that are defining or operating in these locations need to have a dangerous location qualification that considers them skilled. Jobs in these markets are extremely satisfying so you require to be prepared. To satisfy this demand for the industry, nationally recognised training in Certification IV in Dangerous location Electrical and EEHA training on the development of experienced professionals.

Getting The Roar Solutions To Work

Tech Skills Australia is a Registered Training Organization giving you with one of the most affordable and quickest means in obtaining your certification - Roar Training Solutions. Our instructors are market certified and have a number of years of procedure experience. Our courses have actually aided thousands of individuals from business supervisors to day-to-day staff members in getting a strong hold on this not so challenging however high danger training

The training likewise includes identifying the dangerous areas, resources of surge and the residential properties of hazardous materials together with the obligations and features of all celebrations, policies, systems, standards and technique codes linked to unsafe areas. We offer instrumentation and hazardous area services that are in conformity to most current AS/NZS and international sector standards.

Report this page